Transfer Film Characterization

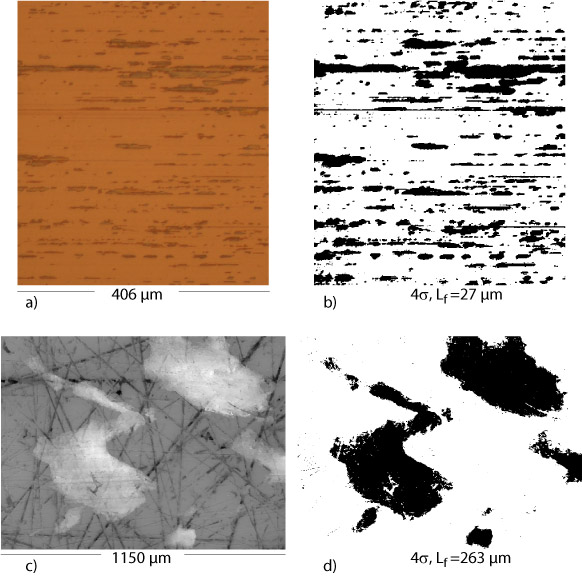

We have developed a program using MatLab to quantitatively characterize trasnfer film quality. The Wear article, Quantitative Characterization of Solid Lubricant Transfer Film Quality, describes the rationale behind the code's development. The output is a single parameter descriptor of the characteristic length of bare areas of counterface. We propose that the size-scale of these domains influence wear by limiting the characteristic size-scale of adhesive contacts and the resulting debris. At the limit of 100% coverage, this size-scale is reduced to zero and wear rates approach an assymtotic limit for the self-mated solid lubricant.Calibration images from the paper are provided to the right; you should be able to duplicate the free-space length of the transfer film for each. The automated mode helps to locate the approximate free-space length. We recommend manual iteration with large sampling sizes (~5000) for final calculations. Manual mode is also useful for obtaining statistics.

Click here to access the Transfer Film Characterization Code

Click here to access a tutorial

Right click and save bmp calibration images:

(a) (b) (c) (d)