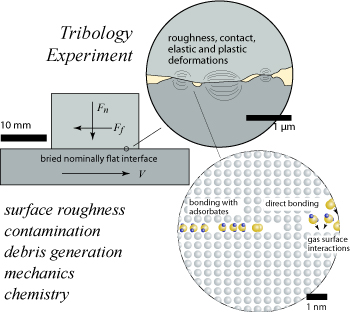

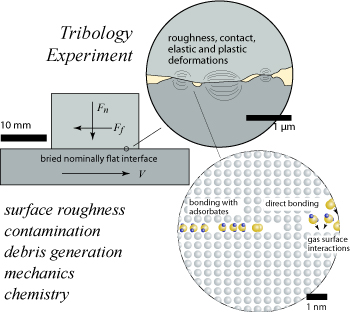

Nanoscale interactions at small areas of direct contact within the buried interface are responsible for the friction observed for macroscopic bearings.

Tribology

Tribology is the science and technology of interacting surfaces in relative motion and the related matters including friction, wear and lubrication.

Origins of 'Tribology'

The word 'tribology' was born ca. 1965 during an investigation of the lubrication needs of industry for the British government. Peter Jost and his collaborators found that the area they were studying involved much more than lubrication; they found a truly interdisciplinary science embracing physics, chemistry, materials science and mechanical engineering. With help from the editor of Oxford English Dictionary, Jost named the 'new' scientific field Tribology after the Greek word 'tribos' - rubbing. See

Machinery Lubrication for an interesting interview with Prof. Jost.

Sketches from da Vinci's notebook, ca. 1480 demonstrating some of his notable friction experiments.

Historical Aspects

Although the term ‘tribology’ is less than half a century old and unfamiliar to most engineers, the field is one of the oldest in science. Lubrication practices and friction management date back thousands of years to the ancient Egyptians who documented the use of lubricated sledges to move a large statue. Leonardo da Vinci recognized the importance of friction, lubrication and wear, and subsequently conducted the first systematic tribology studies to support his machine designs.

Da Vinci first (although informally) noted the two basic laws of friction in the late 1400's. Amontons rediscovered these laws 200 years later and in the late 1700's, Coulomb formalized the second law, stating that the strength of the friction is proportional to the compressive force. Bowden and Tabor provided the first fundamental insight into these empirical 'laws' by demonstrating the relationship between normal force and 'real' area of contact. Modern instruments are accelerating our progress toward the next great fundamental breakthroughs in the field.

Despite the numerous tribological advancements of modern science, tribology remains a barrier to advancement for critical areas including wind power generation, Micro- and Nano-Electrical Mechanical Systems (MEMS & NEMS) and remote military operation. There is also enormous potential for reduced national spending, energy consumption and global pollution through modest improvements in friction and wear in the industrial and transportation sectors.

Broad Impacts

The consequences of tribological phenomena are costly. Jost and his team found that the British industry and government could save considerable money by making proper use of existing (1966) tribological technology. Recent estimates suggest that the results of improper use of modern lubrication techniques cost the U.S. about ~2-6% of the GNP (~$270-800 billion yearly).

Energy has become a huge global concern. It is estimated that over one third the worldwide energy production is consumed by excessive friction and wear in existing products and manufacturing technologies. Small improvements in our ability to manage friction and prevent wear compound to produce cost and energy savings throughout the life cycles of products: energy extraction, energy conversion, parts manufacturing, product operation and recycling all consume excess energy and cost. The US secretary of energy recognizes the important implications of energy efficiency improvements. At a 2008 energy conference at the University of Delaware, he identified improved energy efficiency as his 'first tenet' and offered that

the greatest source of new energy is the energy we waste today.

For thousands of years, tribology has been a barrier to technological innovation. Many emerging technologies are mobile, and thus require tribological components. New technologies place novel demands on the sliding components and many require equally innovative lubricants and lubrication strategies to become practical. A few examples lie in the broad areas of sliding electrical contacts, MEMS devices, space exploration and communications, military operations, medical implants and sustainable energy strategies. Although rarely recognized, tribological research and advancement are strongly tied to the global economy, energy consumption and technological innovation.