Welcome

Wecome to the Materials Tribology Laboratory. Our overarching research mission is to better understand how material properties can be tailored to control the friction and wear of materials. The lack of access to the buried tribological interface is one of the primary barriers to progress in this area. Our group specializes in the development of

in-situ methods to gain more direct access to interfacial processes and phenomena. Our research activities involve instrument design, software developments, materials synthesis, materials characterization, and surface analysis. Our current areas of interest have applications in healthcare, national security, and energy sustainability.

News and Recognition

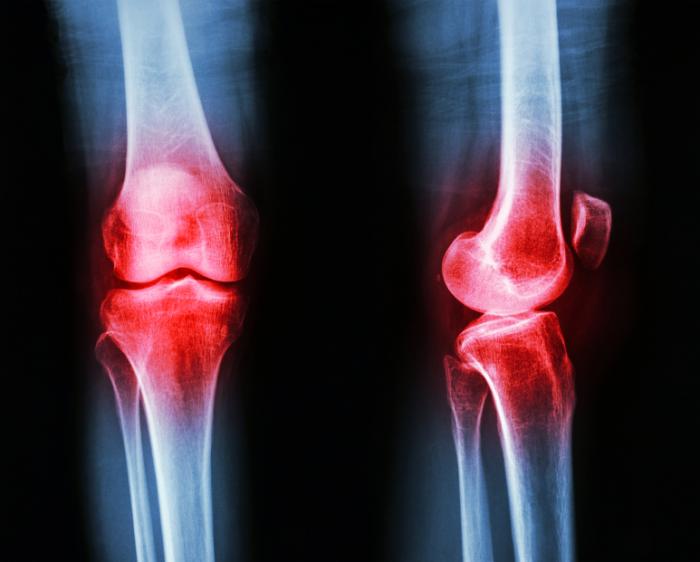

MTL research highlighted for osteoarthritis implications

Yvetee Brazier examines the implications of Axel Moore's doctoral research on joint function and lubrication, which suggests that movement is the mechanism that keeps joints lubricated and healthy.

UD Materials Tribology Lab contributes to the Tribology GRC

Current Ph.D. student, Axel Moore, and Ph.D. graduate, Harman Khare, win poster prizes at the Gordon Research conference (GRC) on Tribology. Prof. Burris, one of 20 speakers at the conference, presented "Cartilage Tribology".

Diana Haidar awarded prestigious NSF Fellowship

Diana Haidar, a mechanical engineering student, has been awarded a 2014 Graduate Research Fellowship from the National Science Foundation for her proposal to make aluminum more resistant to scuffing with a novel approach to nanoscale reinforcement. Axel Moore, a biomedical engineering student, was awarded honorable mention for his proposal to elucidate cartilage lubrication mechanis through in-situ tribometry.

Axel Moore awarded 2014 Young Tribologist Award

Biomedical Engineering Ph.D. student, Axel Moore, was awarded a 2014 Young Tribologist Award at the 2014 Annual Meeting of the Society of Tribologists and Lubrication Engineers. Winners are selected based on contribution to the tribology field as evidenced by publication record and excellence of participation in tribology conferences.

Space lubricant study available online in Tribology Letters

Lead author and mechanical enginering student, Harman Khare, describes mechanisms of failure of molybdenum disulphide, a notable space lubricant.

Khare provides an experimentally-driven model of the coupled effects of water, oxygen, and temperature on the tribological response of molybdenum disulphide.

Cartilage lubrication model published in the Journal of Biomechanics

Biomedical Enginering student, Axel Moore, is lead author of a paper describing an analytical model of cartilage lubrication and direct experimental testing. The model predicts interstitial fluid pressurization, the primary mechanism of cartilage lubrication; fluid pressure supports the contact force, stiffens the tissue, shields the matrix from stress, and lubricates the contact.

Prof. Burris to present at the 2014 GRC on tribology

The GRC's "meetings are recognized as the world's premier scientific conference, where leading investigators from around the globe discuss their latest work and future challenges." Professor Burris has been invited to present "Cartilage Tribology" at the 2014 GRC on tribology; he is among roughly 20 speakers invited to presnt on the most cutting-edge and interdisciplinary areas in the field.

Study on environmental poisoning of MoS2 lubricity published in Tribology Letters

Lead author and mechanical enginering student, Harman Khare, describes an experimental study to elucidate mechanisms of a well-known problem in space lubrication; environmental poisoning of molybdenum disulphide.

Khare provides experimental evidence that water and oxygen have independent effects at low and high temperatures, respectively.

Axel Moore awarded prestigious Laird Fellowship

Axel Moore was named the 2013 Laird Fellow. The Laird Fellowship is given to the UD student who best exemplifies balanced excellence, combining demonstrated intellectual capability with a strong emphasis placed on human qualities such as character, maturity, sense of humor, creativity, ingenuity, and imagination, coupled with practical skills, perseverance and the common sense necessary to execute ideas.

Ben Gould publishes wind turbine drivetrain reliability research in TLT

Ben Gould won Best Poster for "Wind shear increases radial loads on wind trubine drivetrains at the 2012 ASME/STLE International Joint Tribology Conference. The work was published in the August issue of Tribology and Lubrication Technology, STLE's technical magazine.

AFM force calibration published in Review of Scientific Instruments

Lead author and mechanical enginering student, Harman Khare, describes a robust method for calibrating lateral force signals from Atomic Force Microscopes (AFM). The method improves upon prior methods by reducing the effects or probe radius, instrument misalignments, and probe offset. These instrument-related factors are known to cause large force and friction coefficient uncertainties using existing methods.

Axel Moore awarded the AMTI Force and Motion Scholarship

Axel Moore was one of two national recipients of the AMTI Force and Motion Schalarship. The scolarship is given to students studying biomechanics or orthopedics using multi-axial force measurements based on research novelty, clarity of communication, and future research potential .

Study of transfer film evolution elucidates role in wear prevention

Lead author and mechanical enginering student, Jiaxin Ye, uses

in-situ techniques to track the evolution of transfer films produced by an ultra-low wear nanocomposite.The results showed three distinct transfer film morphologies associated with run-in, the transition to low wear, and low wear. Small debris produced at the beginnig of the transition phase strongly adhere to the counterface and nucleate the coherent low wear.

Harman Khare publishes nanotribology research in TLT

Harman Khare won Best Poster for "Methods of characterizing nanoscale friction of solid lubricants" at the 2012 STLE Annual Meeting. The work was published in the September 2012 issue of Tribology and Lubrication Technology, STLE's technical magazine.

Edward Bonnevie wins prestigious NSF Research Fellowship

Edward Bonnevie was awarded a 2012 Graduate Research Fellowship from the National Science Foundation. The fellowship is awarded to outstanding students pursuing research-based master's and doctoral degrees in STEM disciplines.

Harman Khare publishes nanotribology research in TLT

Harman Khare won Best Poster for "Characterization of nanoscale surface films of solid lubricants" at the 2011 ASME/STLE International Joint Tribology Conference. The work was published in the May 2012 issue of Tribology and Lubrication Technology, STLE's technical magazine.

Edward Bonnevie publishes cartilage research in TLT

Edward Bonnevie won the Platinum Poster award for Rate-dependent deformation response of articular cartilage" at the 2011 STLE Annual Meeting. The work was published in the October 2011 issue of Tribology and Lubrication Technology, STLE's technical magazine.