The long-time (steady-state) velocoty field

In this session we solve an unsteady flow and heat transfer in a mixing elbow using Gambit and FIDAP.

Note that the geometry dimensions are given

in inches, while other properties are in SI units.

Geometry and parameters:

The long-time (steady-state) velocoty field

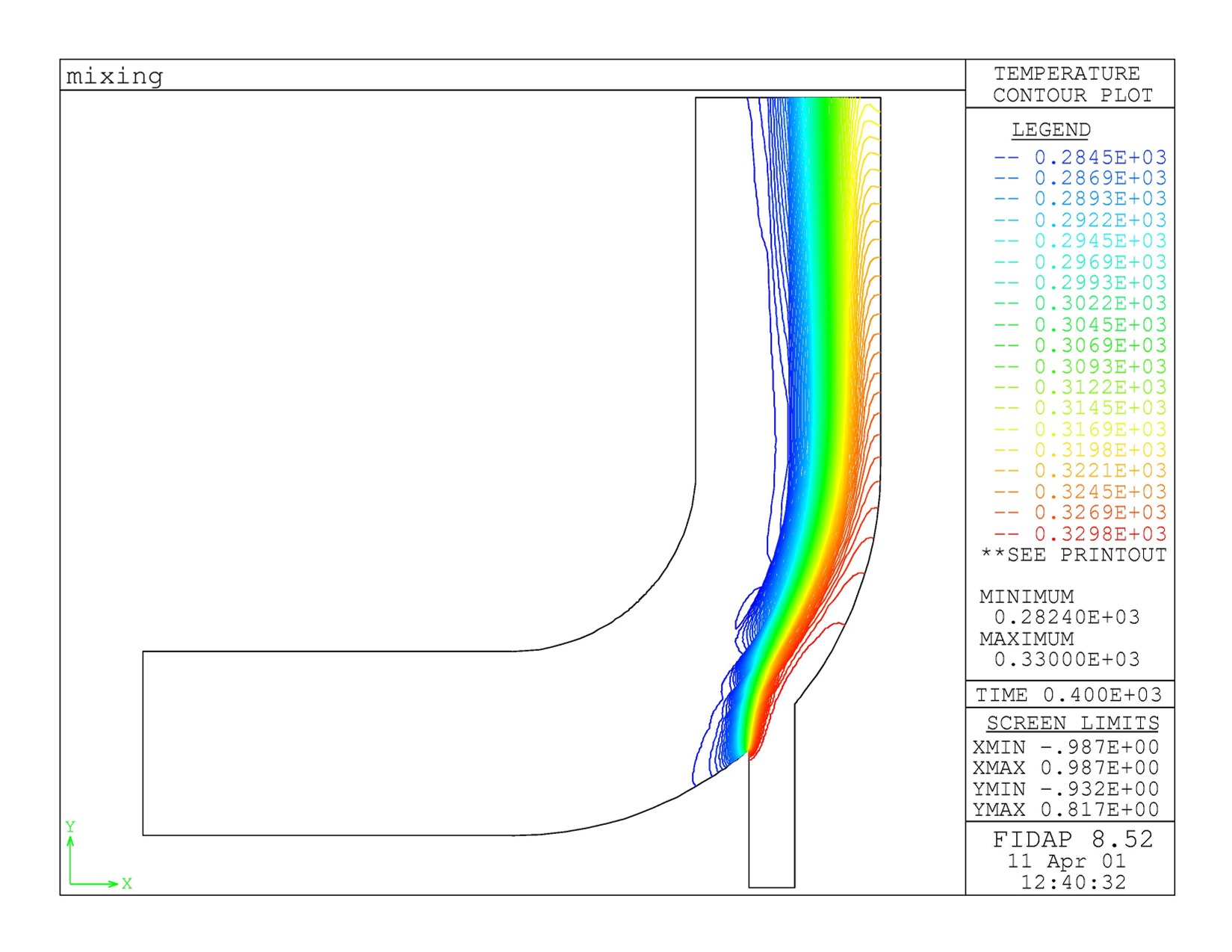

The long-time (steady-state) temperature distribution for laminar flow.

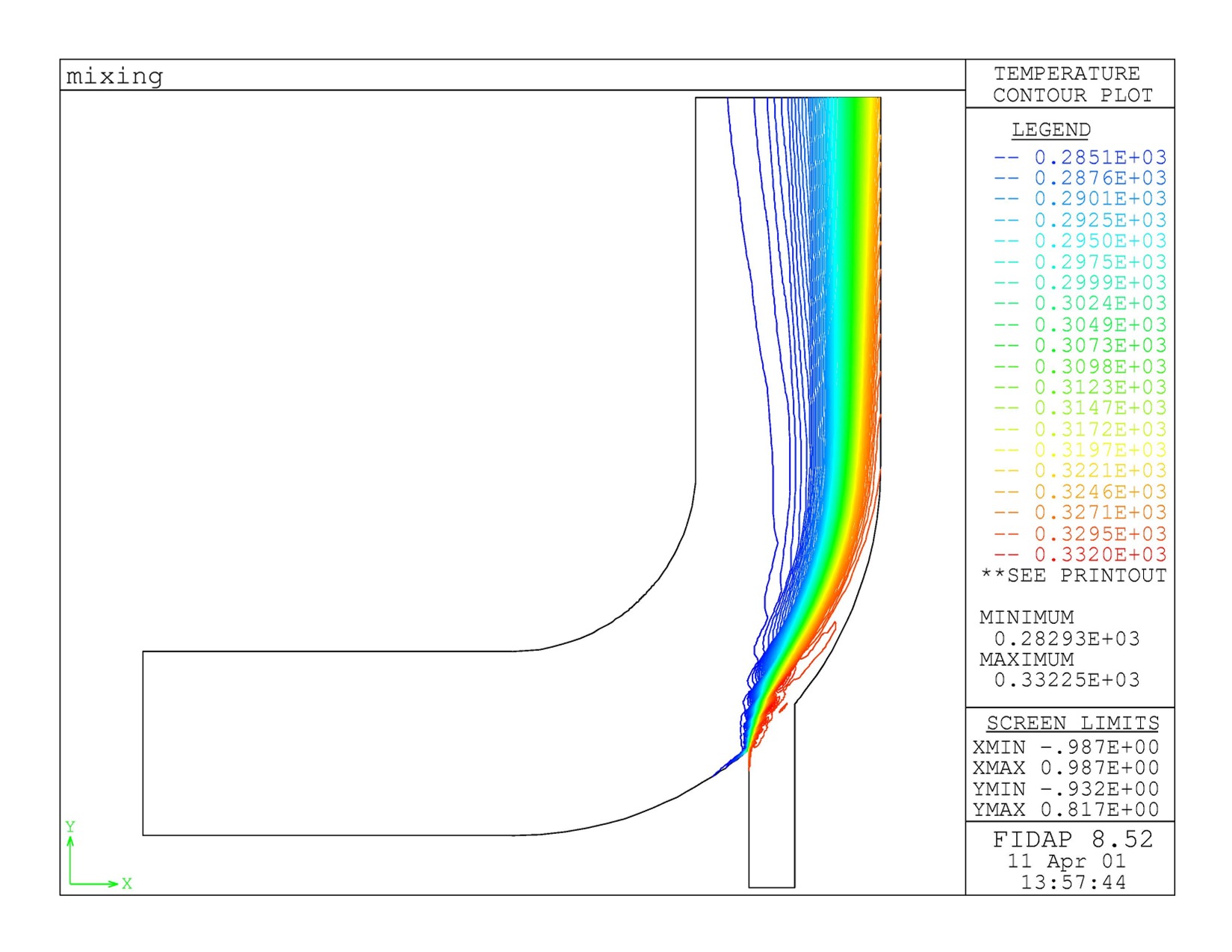

The steady-state temperature distribution for turbulent flow.

Temperature at the center of the outlet at a function of time (laminar flow).

General Instructions for Setting up the

model of mixing elbow

gambit -id mixing -dev X -new

1. Select a solver

Solver - FIDAP

2. Display 4x4 grid covering -32 < x < 32, -32 < y < 32 using

Tools - Coordinate System - Display Grid

3. Pick 9 vertices

(-32, -32) (0.,-32) (-32,-16) (0,-16)

(0., 0. ) (16, 0.) (32, 0.)

(16, 32) ( 32,32)

using Crtl + right click

4. Remove grid by deselecting Visibility

5. Create Arcs for the bend of the mixing elbow

Geometry - Edge - Create Edge - Arc

Shift + left click at point (0., 0.) !define the center

Left click End-Points field

Shift + left click at points (16,0.) (0, -16) !define end points

Apply

Repeat to create the outer arc.

6. Creat straight edges

Geometry - Edge - Create Edge - Straight

Shift + left click to select points, then apply

7. Create the small pipe for the mixing elbow

Geometry - Edge - Split/Merge Edges

Select the large arc

Type = Cylindrical

local t = -39.93

Apply

Select the larger portion of the nearly created arc

local t = -50.07

Apply

Geometry - Vertex - Move/Copy Vertices

! Make a copy of nearly created vertex by shifting in y by -12

Click Fit-to-Window

Create another vertex by copying and shifting in x by 4

Create the edges

8. Create faces from egdes

Geometry - Face - Create Face

Shift + left click each edge of teh large pipe, in turn, to form

a continuous loop

Apply

Repeat for the small pipe

9. Specify node distribution

On Inlet and Outlet of te large pipe:

Mesh - Edge - Mesg Egdes

Select inlet and outlet

Grading = Apply, Type = Successive Ratio

Ratio = 1.25

Double Sided is on

Use 10 interval counts

Apply

4 straight edges of the large pipes

use 15 equal intervals

Large arcs:

6 equal intervals for the center part

12 graded intervals, ratio =0.9

(make sure arrow pointing towards the small pipe,

Use shift-middle click to change direction)

Inner arc:

double sided, ratio = 0.85

Turn off Option / Mesh !Let gambit decide the mesh later

Apply

10. Create structured mesh:

Mesh-Face-Mesh Faces

Select the large pipe

Elements = Quad

Type = Map

11. Mesh the small pipe:

Select the small pipe

Elements = Quad

Type = Map

Spacing = 1

Apply

12. Set Boundary Types

Specify model Display Attributes - Mesh = off - Apply

Zones - Specify boundary types

name = inflow1, type = plot, Entity/Edges (select large pipe inlet), Apply

name = outflow, type = plot, Entity/Edges (select large pipe outlet), Apply

name = inflow2, type = plot, Entity/Edges (select small pipe inlet), Apply

name = walls, type = plot, Entity/Edges (select all wall edges), apply

13. Export neutral file

Export - Mesh - Accept

14. Exit - Save

This will generate:

*.jou: a journal file

*.trn: a summary file

*.FDNEUT: a neutral file

*.FIPREP: FIPREP file

15. Start fidap: fidap -id mixing -gui -new

Read mixing.FIPREP

16. Set up boundary and initial conditions according to the following:

/

FIPREP

PROB (2-D, INCO, TRAN, LAMI, NONL, NEWT, MOME, ENER, FIXE, NOST, NORE, SING)

EXEC (NEWJ)

SOLU (S.S. = 20, VELC = 0.100000000000E-02, RESC = 0.100000000000E-02,

ACCF = 0. )

/

TIME (BACK, NSTE = 400, TSTA = 0. , DT = 0.1, TEND=800., VARI, WIND, NOFI, DTMA = 2.0)

DATA (CONT)

/ Define a second coordinate system centered at large pipe inlet, Mesh Data - Coordinate

COOR (SYST = 2, CART)

-0.3200000000E+02, -0.2400000000E+02, 0.0000000000E+00

PRIN (NONE)

/ Save the results every 4 steps

POST (NBLO = 1, NOPT, NOPA)

4, 400, 4

/ convert inch to m by SCAL, Mesh Data - Scale

SCAL (VALU = 0.254000000000E-01)

ENTI (NAME = "fluid", FLUI)

ENTI (NAME = "inflow1", PLOT)

ENTI (NAME = "inflow2", PLOT)

ENTI (NAME = "outflow", PLOT)

ENTI (NAME = "walls", PLOT)

DENS (SET = 1, CONS = 1.18)

VISC (SET = 1, CONS = 0.184000000000E-04)

SPEC (SET = 1, CONS = 1005.0)

COND (SET = 1, CONS = 0.260000000000E-01)

BCNO (UX, ENTI = "inflow2", ZERO)

BCNO (UY, ENTI = "inflow2", CONS = 0.100000000000E-01, EXCL)

BCNO (TEMP, ENTI = "inflow2", CONS = 330.0, EXCL)

BCNO (UX, ENTI = "inflow1", POLY = 1, SYST = 2, CART)

0.1000000000E-01, -0.1562500000E-03, 0.0000000000E+00, 0.2000000000E+01,

0.0000000000E+00

BCNO (UY, ENTI = "inflow1", ZERO)

BCNO (TEMP, ENTI = "inflow1", CONS = 283.0)

BCNO (VELO, ENTI = "walls", ZERO, X, Y, Z)

/ The walls are adiabatic by default

ICNO (VELO, ZERO, ENTI = "fluid", X, Y, Z)

ICNO (TEMP, CONS = 283.0, ENTI = "fluid")

END

17. Run and postprocessing

You can use Utility/Timestep to select the time step for displaying the results.

Plot / History can be used to plot time-evolution results at any node.

Turbulent Flow:

Lecture on turbulence modeling

The inlet velocity is assumed to be 10 m/s at both inlets. two-equation k.e.-dissipation

model is used. The boundary conditions for k.e. and dissipation are: k.e. = 0.035 u^2, diss = 0.01 u^3/D.

FIPREP

PROB (2-D, INCO, STEA, TURB, NONL, NEWT, MOME, ENER, FIXE, NOST, NORE, SING)

PRES (PENA = 0.100000000000E-07, DISC)

EXEC (NEWJ)

SOLU (S.S. = 100, VELC = 0.100000000000E-02, RESC = 0.100000000000E-02,

ACCF = 0.4)

DATA (CONT)

OPTIONS(UPWINDING)

UPWINDING

1 1 0 0 2 0 1 1

PRIN (NONE)

SCAL (VALU = 0.254000000000E-01)

ENTI (NAME = "fluid", FLUI)

ENTI (NAME = "inflow1", PLOT)

ENTI (NAME = "inflow2", PLOT)

ENTI (NAME = "outflow", PLOT)

/

ENTI (NAME = "walls", WALL)

/ Here the ENTITY Type = WALL is very important, so that the walls will be treated with special wall elements

/ in the turbulence modeling

/

TURBCONSTANTS

0 0 0 0 0 0 0.9

/ Turbulent Prandtl number = 0.9, Other model constants are set to default

DENS (SET = 1, CONS = 1.18)

VISC (SET = 1, CONS = 0.184000000000E-04, TWO-)

SPEC (SET = 1, CONS = 1005.0)

COND (SET = 1, CONS = 0.260000000000E-01)

BCNO (UX, ENTI = "inflow2", ZERO)

BCNO (UY, ENTI = "inflow2", CONS = 10.0, EXCL)

BCNO (TEMP, ENTI = "inflow2", CONS = 330.0, EXCL)

/ k.e. = 0.035 u^2 , diss = 0.01 u^3/D

/

BCNO (KINE, ENTI = "inflow2", CONS = 3.5)

BCNO (DISS, ENTI = "inflow2", CONS = 98.4)

/

BCNO (UY, ENTI = "inflow1", ZERO)

BCNO (UX, ENTI = "inflow1", CONS = 10.0, EXCL)

BCNO (TEMP, ENTI = "inflow1", CONS = 283.0)

BCNO (KINE, ENTI = "inflow1", CONS = 3.5)

BCNO (DISS, ENTI = "inflow1", CONS = 24.6)

/

BCNO (VELO, ENTI = "walls", ZERO, X, Y, Z)

ICNO (VELO, ZERO, ENTI = "fluid", X, Y, Z)

ICNO (TEMP, CONS = 283.0, ENTI = "fluid")

ICNO (KINE, CONS = 3.5, ENTI = "fluid")

ICNO (DISS, CONS = 24.6, ENTI = "fluid")

END