MEEG 681 / MEEG481

Computer Solution of Engineering Problems

Computer Session 7

In this session we solve an unsteady water flow around a two-dimensional

cylinder using FIDAP.

Step-by-Step FIDAP Instructions for Setting up the

model

1. Starting the FID AP GUI:

cd /tmp

mkdir mydir (make a new directory)

cd mydir (Always start in a new, empty directory)

fidap -id 2Dcyld -gui (start a FIDAP session named 2Dcyld)

click the "FIDAP version window" to remove it

2. Start up FI-GEN (the mesh generation module):

-

Click FI-GEN

-

Click Accept (after a few seconds a graphical window appears)

3. Generating the Geometry (i.e., Points, Curves and Surfaces):

-

select Point

-

click Add under COMMAND OPTION

-

Enter the coordinates of the following 7 points: (0,0), (10,0), (10,5),

(0,5), (2.0,2.5), (2.5,2.0), (3.0,2.5) (will be referred to as points 1,

2, 3, 4, 5, 6, 7 in this order)

-

Move the cursor into the graphical window and type the letter "F" to bring

all the 7 points into the window (you should see all the 7 points, each

marked by a plus sign)

-

Click Curve (1)

-

Select ADD Line under COMMAND OPTION

-

Left click the points 1-2-3-4-1 in order in the graphical window, and then

right click

-

Select Curve(2)

-

click ADD circle

-

Left click points 5, 6, and 7, then right click (a circle is drawn)

-

Select Surface

-

Click ADD by W/F

-

Left click the 4 lines connecting the points 1-2, 2-3, 3-4, 4-1 in order,

then right click

4. Creating mesh:

-

Click Mesh Edge , Select ADD

-

Input 25 in the "Interval" box field

-

Left click the two vertical lines connecting the points 4-1,2-3;

-

Right click (you should see 26 nodes on each of the vertical line)

-

Input 40 in the "Interval" box field

-

Left click the two horizontal lines connecting the points 1-2,3-4; then

right-click

-

Input 20 in the "Interval" box field

-

Left click the circle, Right click

-

Select Mesh Loop , click Add Pave

-

Left click the 4 lines connecting the points 1-2, 2-3, 3-4, 4-1 in order,

then right click

-

Left click the circle, then right click

-

Select Mesh Face, click ADD

-

left-click on the dark blue surface cross bar, right-click

-

left-click on the outside square, then left-click on the inner circle,

right-click

-

Select Bndry Edge , click Add

-

Select Layers under BOUNDARY EDGE DEFAULTS

-

Input 0.2 in the Height 1 field, 1.1 in the Growth factor field, and 3

in the No. Layer field

-

left-click on the mesh face boundary, right click

-

left-click on the circle, right click (You should see Be mark near the

circle)

-

Select Mesh Face, click Mesh

-

Click "All" under SELECT OPTION

-

Click "Pave" under MESH FACE DEFAULTS

-

Input "fluid" in the "Entity" box

-

Right click in the graphical window (Now mesh is being generated, this

may take a few minutes)

5. Specifying entity names for the boundaries:

-

Click Mesh Edge

-

Select MESH MAP

-

Left click the line connecting points 1 and 2

-

Input "bottom" in the "Entity" field

-

Right click in the graphical window

-

Left click the line connecting points 3 and 4

-

Input "top" in the "Entity" field

-

Right click in the graphical window

-

Left click the lines connecting points 4-1

-

Input "inlet" in the "Entity" field

-

Right click in the graphical window

-

Left click the lines connecting points 2-3

-

Input "outlet" in the "Entity" field

-

Right click in the graphical window

-

Left click the cylinder

-

Input "cylinder" in the "Entity" field

-

Right click in the graphical window

-

Click END once to exit FIGEN

6. Defining entity labels

-

Click FIPREP, Select "Entity"

-

Left click the question mark to select "fluid" entity

-

Input "Fluid" in the ENTITY TYPE field, Right click ADD-ADD (REPEAT)

-

Left click the question mark to select "bottom" entity

-

Input "plot" in the ENTITY TYPE field, Right click ADD-ADD (REPEAT)

-

Repeat this for the other boundary entities: "top", "inlet", "outlet",

"cylinder".

7. Specifying fluid properties

-

Click Properties

-

Click "DENSITY"

-

Input 0.998 in the MODEL TYPE-CONSTANT field

-

Click ADD

-

Click "VISCOSITY"

-

Input 0.01003 in the MODEL TYPE-CONSTANT field

-

Click ADD

8. Specifying boundary conditions

-

Click Boundary C., Click BCNODE

-

Right-click exclamation point next to DEGREE of FREEDON, Pick VELOCITY

-

Right-click exclamation point next to REGION SELECTION, Pick ENTITY

-

Left-click question mark beside REGION SELECTION field, Pick "cylinder"

-

Right-click exclamation point next to VALUE GENERATION field, Pick Zero

-

Right-select ADD(REPEAT)

-

Right-click exclamation point next to DEGREE of FREEDON

-

Pick UX

-

Left-click question mark beside REGION SELECTION field, Pick "inlet"

-

Right-click exclamation point next to VALUE GENERATION field

-

Set CONST ANT to 1.0

-

Right-select ADD(REPEAT)

-

Right-click exclamation point next to DEGREE of FREEDON

-

Pick UY

-

Left-click question mark beside REGION SELECTION field, Pick "inlet"

-

Right-click exclamation point next to VALUE GENERATION field

-

Pick Zero, Right-select ADD (REPEAT)

-

Left-click question mark beside REGION SELECTION field, Pick "top"

-

Right-click exclamation point next to VALUE GENERATION field

-

Pick Zero, Right-select ADD(REPEAT)

-

Left-click question mark beside REGION SELECTION field, Pick "bottom"

-

Right-click exclamation point next to VALUE GENERATION field

-

Pick Zero, Right-select ADD

9. Specifying the problem type

-

Select Simulation

-

Click EXECUTION

-

Change EXECUTION MODE to NEWJOB

-

Click ADD

-

Click PROBLEM

-

Change SIMULATION TYPE to TRANSIENT

-

Change CONVECTIVE TERM to NONLINEAR

-

Click ADD

-

Click TIMEINTEGRATION

-

Set NSTEPS=60

-

Set TSTART=0.0

-

Set DT=0.05

-

Click ADD

-

Click END to exit FIPREP

10. Creating the Database

-

Click CREATE

-

Select Create

-

Click ACCEPT

11. Solving the problem

-

Click RUN

-

Pick FISOLV

-

Pick FOREGROUND

-

Click ACCEPT (Now relax and wait for the simulation to finish, this may

take a minute or two)

12. Get ready for post processing

-

Click IDENT

-

Click ACCEPT

-

Click FIPOST

-

Click ACCEPT

13. Visualizing the vector velocity field

-

Click Vector

-

Click Accept

14. Plotting streamlines

-

Click Utility

-

Select TIMESTEP

-

Set to desired time step, click ADD

-

Click Contour

-

Right-click exclamation point next to DEGREE of FREEDON

-

Pick STREAMLINE

-

Input 60 in the CONTOUR LEVELS-AUTOMATIC field (this will draw 60 contour

levels in stead of 10 by default).

-

Click ACCEPT (You can clearly see the re-circulation region)

15. Plot and read results on a line

-

PLOT-LINE: Degree of freedom = UX, LINE DEFINITION=PVECTOR, ACCEPT

-

INPUT: 0.,2.5,0.0,1.,0.0,0.0

-

Also check the results in the *.FIOUT file

16. Compute drag force on cylinder

- Go to FIPOST

- Computation - STRSPRINT - Stress Type=Total, Sides definition =Entity.Cylinder, Accept

- In the History window, the X Total Force is the drag.

17. Exit FIDAP (always remember to exit FIDAP properly)

-

Click END to exit FIPOST

-

Click END one more time to exit FIDAP

-

Answer YES to the EXIT PROMPT question

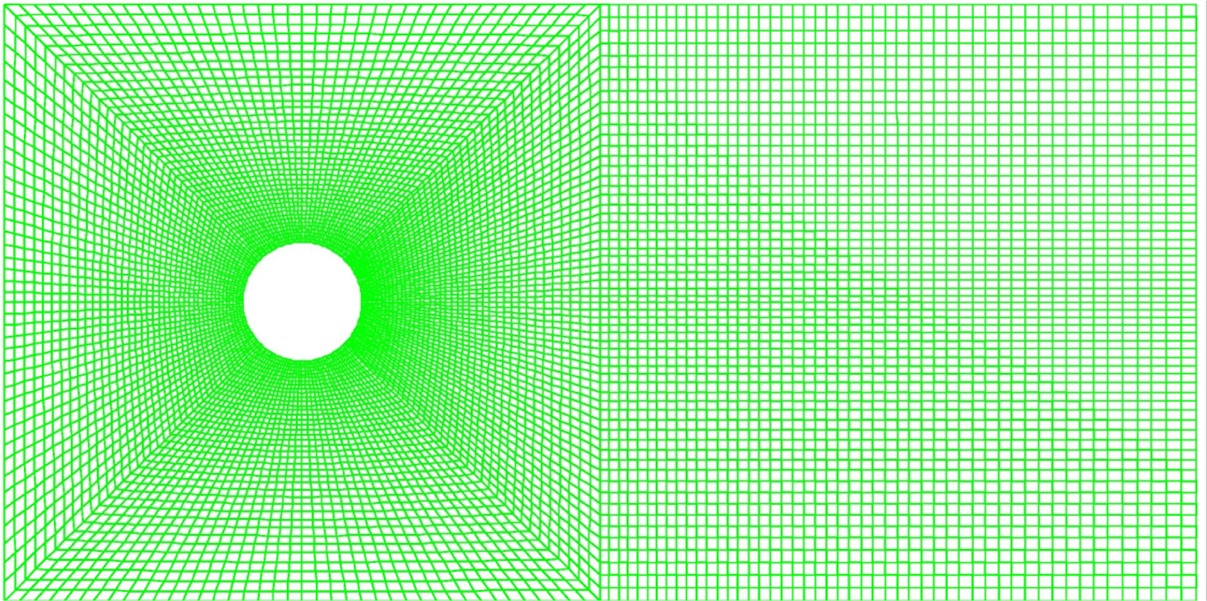

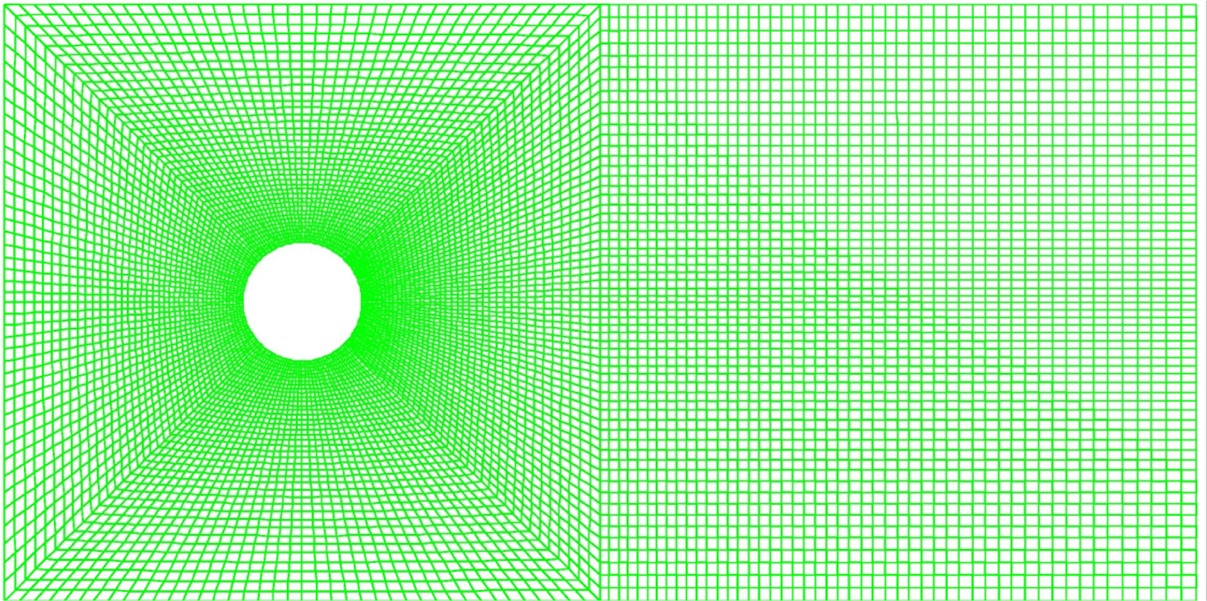

Using Gambit to model the problem with a different mesh

/ Journal File for GAMBIT 1.3.0

/ File opened for write Wed Apr 4 11:19:03 2001.

identifier name "cylind" new saveprevious

undo begingroup

vertex create coordinates 0 0 0

undo endgroup

undo begingroup

vertex create coordinates 5 0 0

undo endgroup

undo begingroup

vertex create coordinates 10 0 0

undo endgroup

undo begingroup

vertex create coordinates 10 5 0

undo endgroup

undo begingroup

vertex create coordinates 5 5 0

undo endgroup

undo begingroup

vertex create coordinates 0 5 0

undo endgroup

undo begingroup

/

vertex create coordinates 2.5 2.510 0

/ This introduce a little bit of asymmetry to the domain to help generate

/ vortex shedding

/

undo endgroup

edge create radius 0.5 startangle 45 endangle 135 center "vertex.7" xyplane arc

edge create radius 0.5 startangle 135 endangle 225 center "vertex.7" xyplane arc

edge create radius 0.5 startangle 225 endangle 315 center "vertex.7" xyplane arc

edge create radius 0.5 startangle 315 endangle 45 center "vertex.7" xyplane arc

vertex connect "vertex.1" "vertex.2" "vertex.3" "vertex.4" "vertex.5" \

"vertex.6" "vertex.7" "vertex.8" "vertex.9" "vertex.10" "vertex.11" \

"vertex.12" "vertex.13" "vertex.14" "vertex.15" real

edge create straight "vertex.1" "vertex.2" "vertex.3" "vertex.4" "vertex.5" \

"vertex.6"

edge create straight "vertex.6" "vertex.1"

edge create straight "vertex.5" "vertex.2"

edge create straight "vertex.6" "vertex.9"

edge create straight "vertex.5" "vertex.8"

edge create straight "vertex.2" "vertex.13"

edge create straight "vertex.11" "vertex.1"

face create wireframe "edge.10" "edge.15" "edge.2" "edge.12" real

face create wireframe "edge.12" "edge.1" "edge.13" "edge.9" real

face create wireframe "edge.4" "edge.14" "edge.11" "edge.13" real

face create wireframe "edge.14" "edge.3" "edge.15" "edge.5" real

face create wireframe "edge.6" "edge.7" "edge.8" "edge.11" real

undo begingroup

edge picklink "edge.10"

edge mesh "edge.10" successive ratio1 0.97 ratio2 0.97 intervals 40

undo endgroup

undo begingroup

edge picklink "edge.11" "edge.7"

edge mesh "edge.7" "edge.11" successive ratio1 0.98 ratio2 0.98 intervals 60

undo endgroup

undo begingroup

edge picklink "edge.4"

edge mesh "edge.4" successive ratio1 0.99 ratio2 0.99 intervals 60

undo endgroup

undo begingroup

edge picklink "edge.3" "edge.2" "edge.1"

edge mesh "edge.1" "edge.2" "edge.3" successive ratio1 1 intervals 40

undo endgroup

undo begingroup

edge picklink "edge.12"

edge mesh "edge.12" successive ratio1 0.97 intervals 40

undo endgroup

undo begingroup

edge picklink "edge.13"

edge mesh "edge.13" successive ratio1 0.97 intervals 40

undo endgroup

undo begingroup

edge picklink "edge.15"

edge mesh "edge.15" successive ratio1 1.03093 intervals 40

undo endgroup

undo begingroup

edge picklink "edge.14"

edge mesh "edge.14" successive ratio1 0.97 intervals 40

undo endgroup

undo begingroup

edge picklink "edge.5" "edge.9"

edge mesh "edge.9" "edge.5" successive ratio1 1 intervals 40

undo endgroup

undo begingroup

edge picklink "edge.6" "edge.8"

edge mesh "edge.8" "edge.6" successive ratio1 1 intervals 40

undo endgroup

face mesh "face.1" "face.2" "face.3" "face.4" "face.5" map size 1

face delete "face.5" onlymesh

undo begingroup

edge delete "edge.8" keepsettings onlymesh

edge mesh "edge.8" successive ratio1 0.99 intervals 50

undo endgroup

undo begingroup

edge delete "edge.6" keepsettings onlymesh

edge mesh "edge.6" successive ratio1 1.0101 intervals 50

undo endgroup

face mesh "face.5" map size 1

solver select "FIDAP"

physics create "fluid" ctype "FLUID" face "face.1" "face.2" "face.3" "face.4" \

"face.5"

physics create "inlet" btype "PLOT" edge "edge.10"

physics create "top" btype "PLOT" edge "edge.9" "edge.8"

physics create "bottom" btype "PLOT" edge "edge.5" "edge.6"

physics create "outlet" btype "PLOT" edge "edge.7"

physics create "cylinder" btype "PLOT" edge "edge.4" "edge.1" "edge.2" \

"edge.3"

export fidap "cylind.FDNEUT"

/ File closed at Wed Apr 4 11:53:02 2001, 15.56 cpu second(s), 4840040 maximum memory.

FIPREP file for the unsteady case

/

/ CONVERSION OF NEUTRAL FILE TO FIDAP Database

/

FICONV( NEUTRAL )

INPUT( FILE="cylind.FDNEUT" )

OUTPUT( DELETE )

END

/

/

TITLE

cylind

/

FIPREP( )

/

EXECUTION( ADD, NEWJ )

/

PROBLEM( ADD, 2-D, INCO, TRAN, LAMI, NONL, NEWT, MOME, ISOT, FIXE, SING )

/

/ TIMEINTEGRATION( ADD, BACK, NSTE = 201, TSTA = 0, DT = 0.25, FIXE )

/ TIMEINTEGRATION( ADD, BACK, NSTE = 201, TSTA = 50.25, DT = 0.25, FIXE )

TIMEINTEGRATION( ADD, BACK, NSTE = 401, TSTA = 100.50, DT = 0.25, FIXE )

SOLUTION( S.S. = 50, VELCONV = .001, RESCONV = .001)

/

POSTPROCESS(NBLOCKS=1)

1 401 4

/

DATAPRINT( ADD, CONT )

PRINTOUT( ADD, NONE, BOUN )

/

ENTITY( ADD, NAME = "fluid", FLUI )

ENTITY( ADD, NAME = "bottom", PLOT )

ENTITY( ADD, NAME = "top", PLOT )

ENTITY( ADD, NAME = "inlet", PLOT )

ENTITY( ADD, NAME = "outlet", PLOT )

ENTITY( ADD, NAME = "cylinder", PLOT )

/

DENSITY( ADD, SET = 1, CONS = 0.998 )

VISCOSITY( ADD, SET = 1, CONS = 0.01003 )

/

/ ICNODE( ADD, VELO, ZERO, ENTI = "fluid", X, Y, Z )

/ To read steady-state flow field as the initial condition:

/ change *.FDPOST to *.FDREST

/ and then

ICNO (VELO, READ)

/

BCNODE( ADD, VELO, ENTI = "cylinder", ZERO, X, Y, Z )

BCNODE( ADD, UY, ENTI = "inlet", ZERO )

BCNODE( ADD, UX, ENTI = "inlet", CONS = 1.00 )

BCNODE( ADD, UY, ENTI = "bottom", ZERO )

BCNODE( ADD, UY, ENTI = "top", ZERO )

/

END( )

CPU TIME for the runs on mahler:

First 201 steps: 6528 s

Next 201 steps: 20398 s

Next 401 steps: 40496 s

Print a hard copy of FIPOST visualizations

-

Click Graphics

-

Click Device

-

Select Postscript as Device driver, then Accept

-

Run FIPOST (all the plots are now saved in a file 2Dbed.FIPLOT)

-

Exit FIDAP

-

fdp2ps

-

Enter 2Dbed.FIPLOT as plot file

-

Name the postscript file as you like

Results for unsteady simulations

Re = 100 (Spring 2001)

Re = 200 (Spring 2002)

How to start a run with initial field specified as the last field of a previous run?

/ change *.FDPOST to *.FDREST

/ and then

ICNO (VELO, READ)

/