Outline and Objectives:

Important things to know about ANSYS:

ansys -g -j jobname

For other start-up options,

see Chapter 3 of Operation Guide.

--------------------------------------------------------

FILE TYPE FILE NAME FILE FORMAT

Log file jobname.log ASCII

Error file jobname.err ASCII

Output file jobname.out ASCII

Database file jobname.db Binary

Results file: Binary

Solid/Structural jobname.rst

Thermal jobname.rth

Fluid jobname.rfl

------------------------------------------------------

The log file is the most important file. It keeps a complete log

of an ANSYS session (list all commands you execute). You can

read the log file, view it while in ANSYS, edit it,

and input it later.

Note: use ! for comments

To input a log file: FILE - Read input from ...

The error file lists all the errors and warnings. You may use

this to edit your log file.

Output file:

containing:

-- Load summary information,

-- mass and moments of inertia of the model

-- solution summary information

-- total CPU time,

-- data requested by the OUTPR output control command

e.g., General Postprocesser - list results - modal -

- print output

If you run the solution interactively, the output

file is actually your screen (window). By doing the following

before issuing SOLVE, you can divert the output

to a file instead of the screen:

File - Switch Output to - File

Database file: Contains all model information

Results file: contains solution data generated during SOLVE steps

PlotCtrls - Style - Size and Shape Plot - Elements

-- graphical display: contour, deformed shape, reaction force.. -- tabular listings (can be saved in the output file)

(1) PlotCtrls: changing graphics specifications

Plot: select graphics action

(2) Replot and Erase:

Plot - Replot

PlotCtrls - Erase Options - Erase Screen

(3) Multi-Plotting Techniques

(a) PlotCtrls - MultiWindow Layout

(b) PlotCtrls - Multi-Plot Controls

(4) Storing a graphics display on a file:

PlotCtrls - Redirect Plots - to Graphics File

Two-dimensional modeling of the Steel Plate using ANSYS

You can use ANSYS to answer the question:

To what extent is one-D solution adequate?

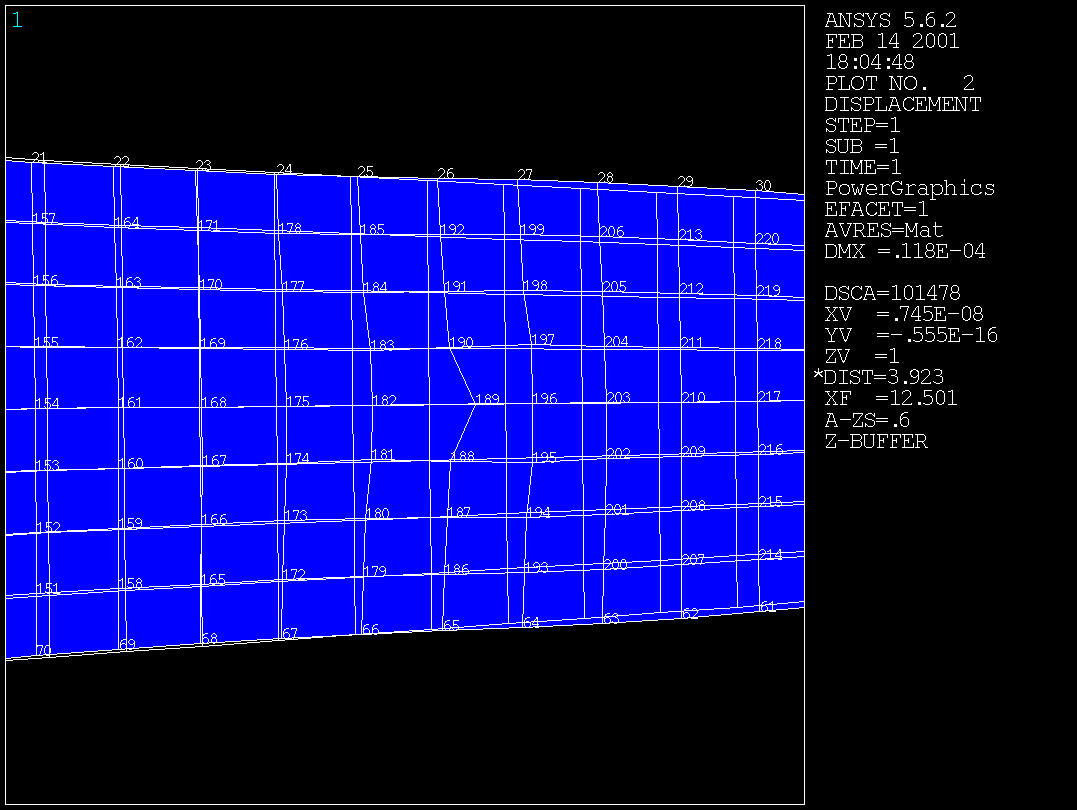

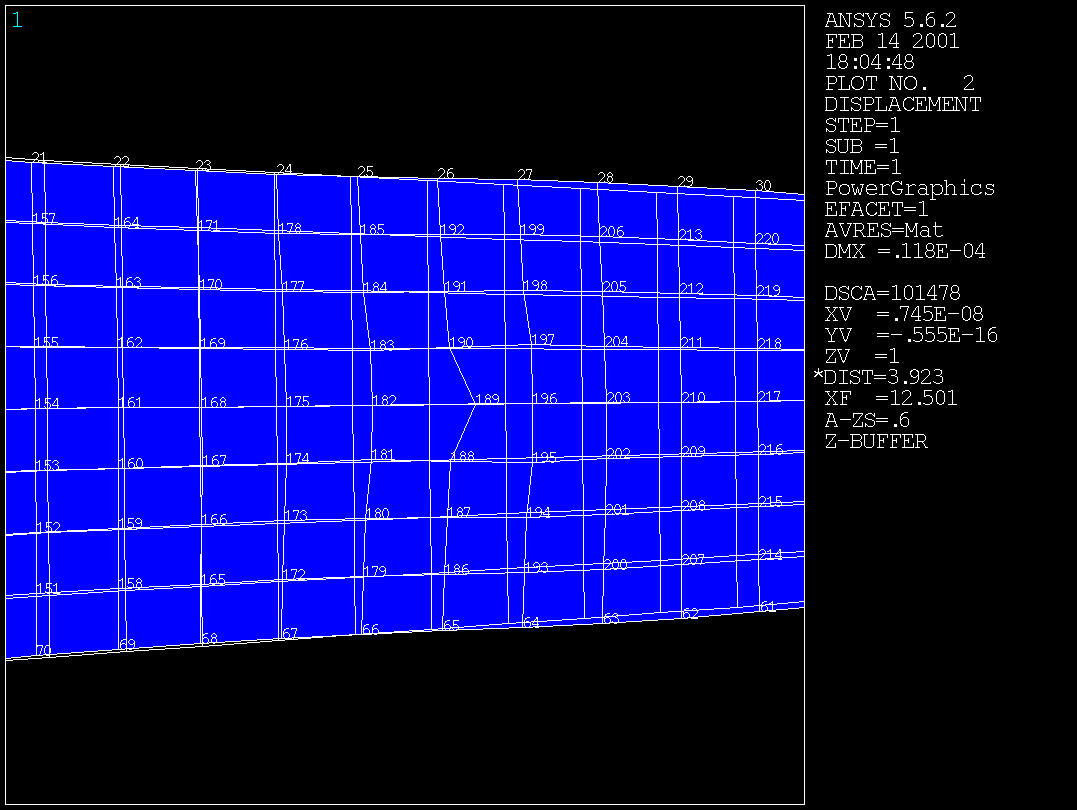

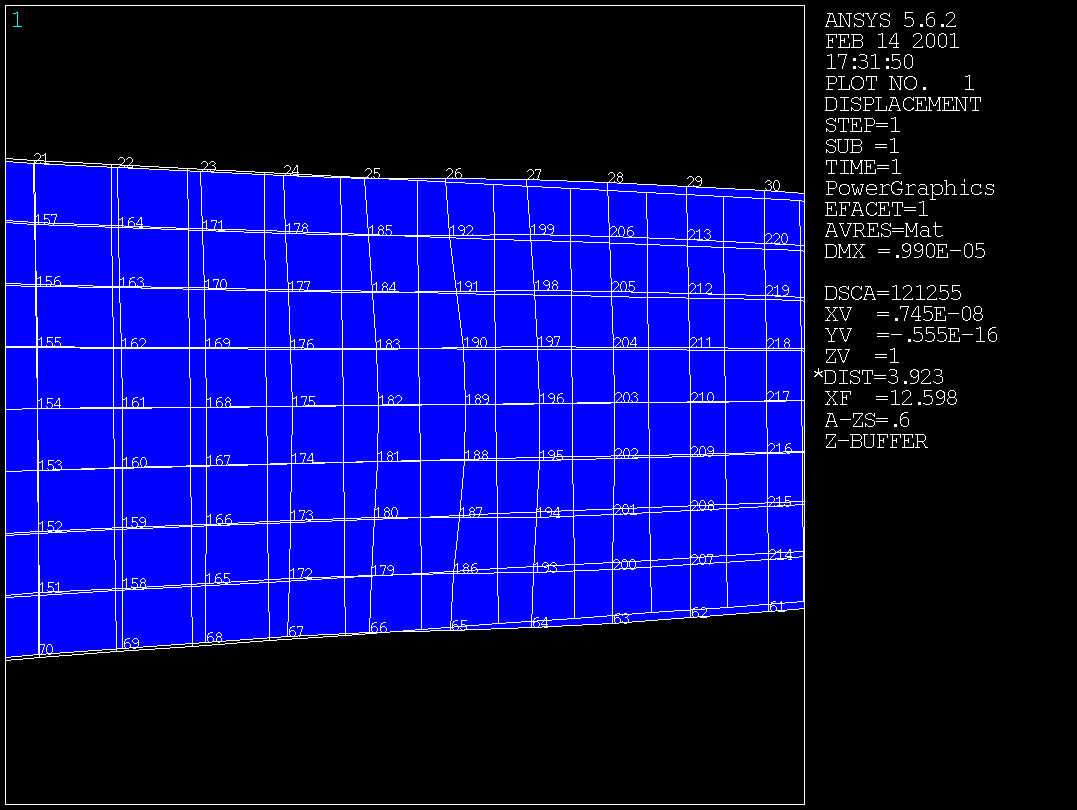

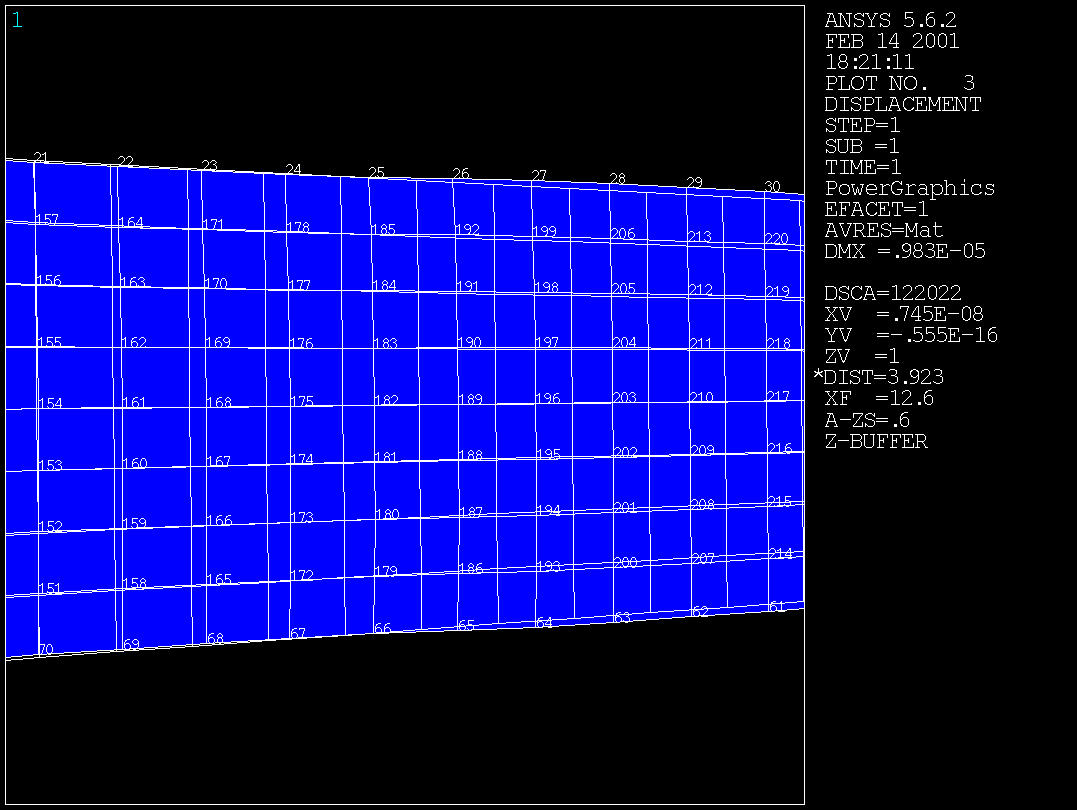

The two-D solid-element model for the Steel Plate problem:

Mesh resolution: 32x8, namely 32 elements in X and 8 elements in Y

Objective: (1) Study the effect of external load distribution

(2) Study the effect of different Poisson ratio

Model Development (for Poisson ratio=0.3, Load over 1/2 of width):

Here are the steps for setting up the model.

| Load distribution / Poission Ratio | Displacement at x=12 and y=0 (Node 189) | Displacement at x=24 and y=0 (Node 46) |

| 1/8 Width / 0.3 | 11.825e-6 | 9.8755e-6 |

| 1/4 Width / 0.3 | 10.601e-6 | 9.8717e-6 |

| 1/2 Width / 0.3 | 9.8965e-6 | 9.8642e-6 |

| Full Width / 0.3 | 9.2886e-6 | 9.8343e-6 |

| 1/8 Width / 0.0 | 11.488e-6 | 9.9281e-6 |

| 1/4 Width / 0.0 | 10.420e-6 | 9.9248e-6 |

| 1/2 Width / 0.0 | 9.8126e-6 | 9.9183e-6 |

| Full Width / 0.0 | 9.3139e-6 | 9.8922e-6 |

| 1D Links (2) | 9.2720e-6 | 9.9527e-6 |

| 1D analytical solution | 9.2707e-6 | 9.8684e-6 |

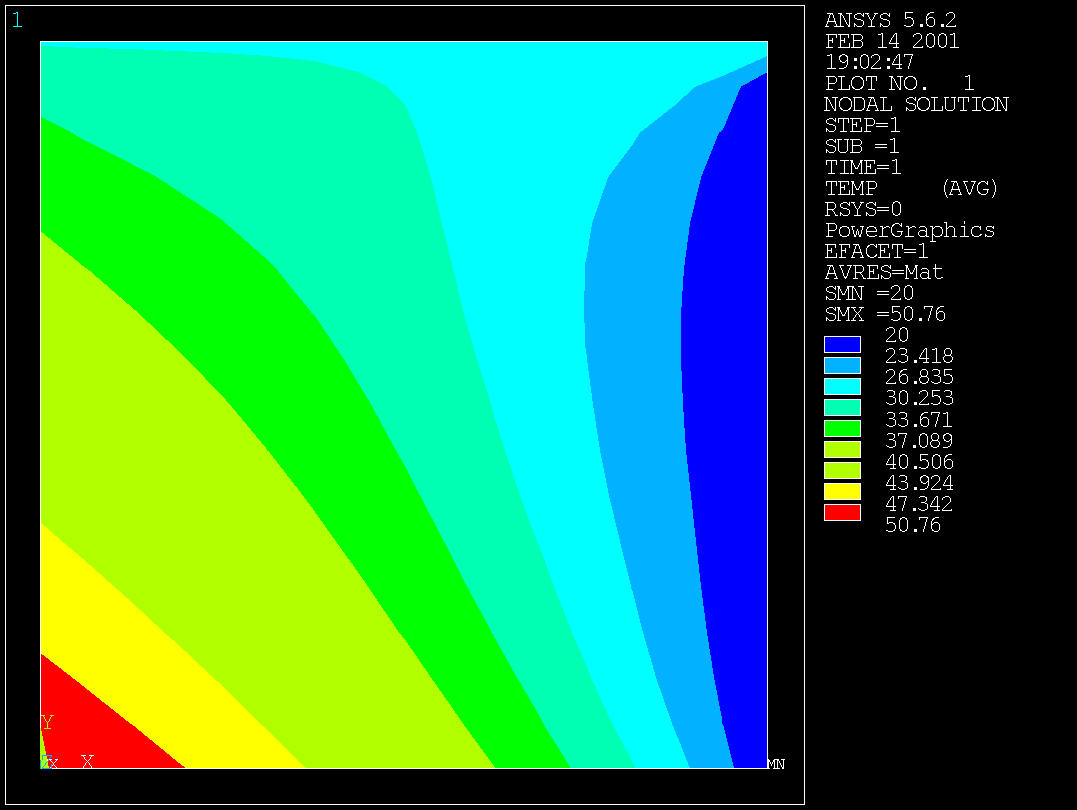

Two-dimensional modeling of heat conduction using ANSYS

Consider heat conduction in an aluminum plate (12in x 12in x 2in thick or 30.5 cm x 30.5 cm x 5.1 cm) subject to the following boundary conditions: Two edges are heated using thermally bonded electrical resistance strip heaters (assume constant heat flux boundary condition) The other two edges are cooled using thermally bonded heat exchanger plates supplied with cooling water from a chiller (assume constant temperature boundary condition) The bottom face is insulated with glass wool The top face is separated from the surroundings by an air gap trapped underneath a glass plate Assume: T1 = 20 C, T2=30 C, q1 = 10000 W/m^2, q2=15000 W/m^2. Material properties: conductivity = 200 W/m.k. Treat this as a 2D heat conduction problem. Solve for temperature distribution.Here are the steps for setting up the model.

Note that you can perform a full three-D solution with ANSYS and compare

that with the 2D results.

Note that you can perform a full three-D solution with ANSYS and compare

that with the 2D results.