Nonlinear Analysis of a 2-D Rubber Seal

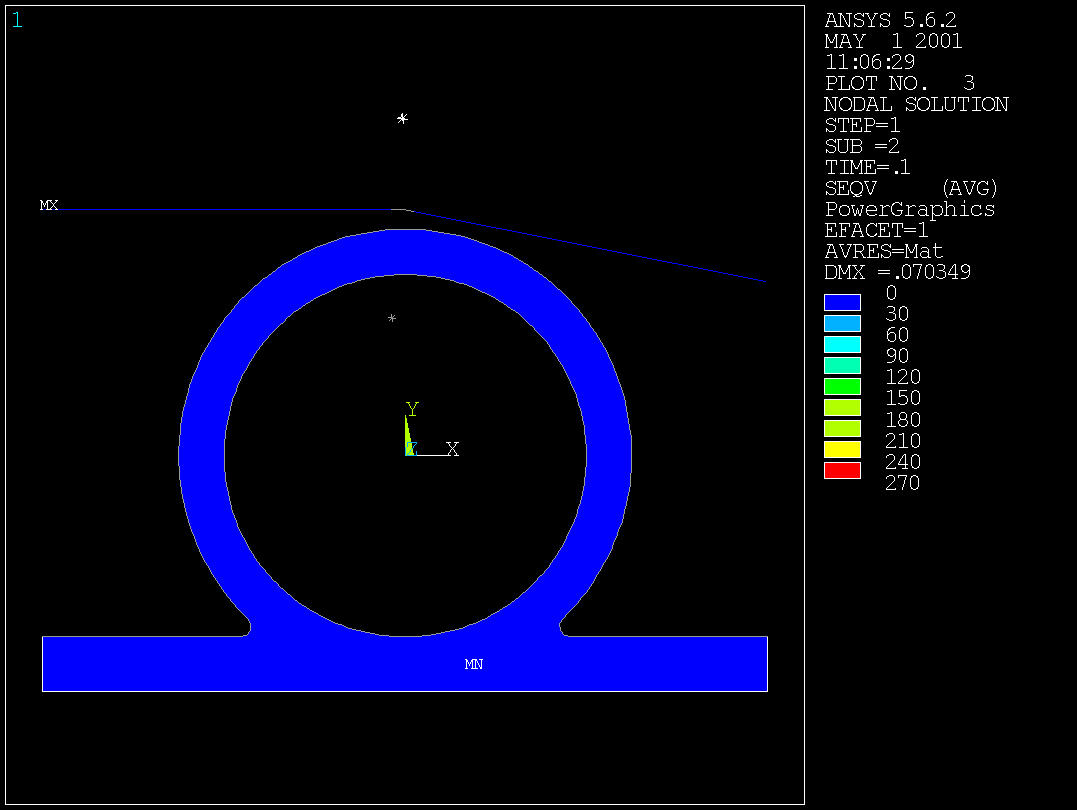

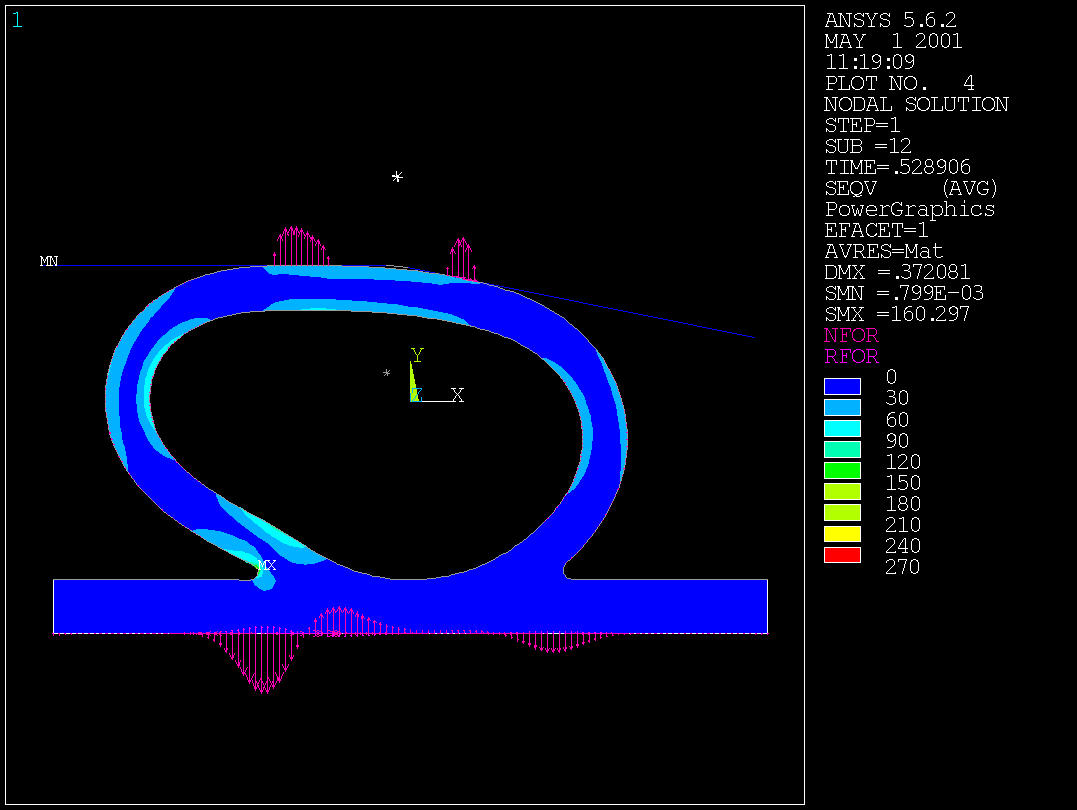

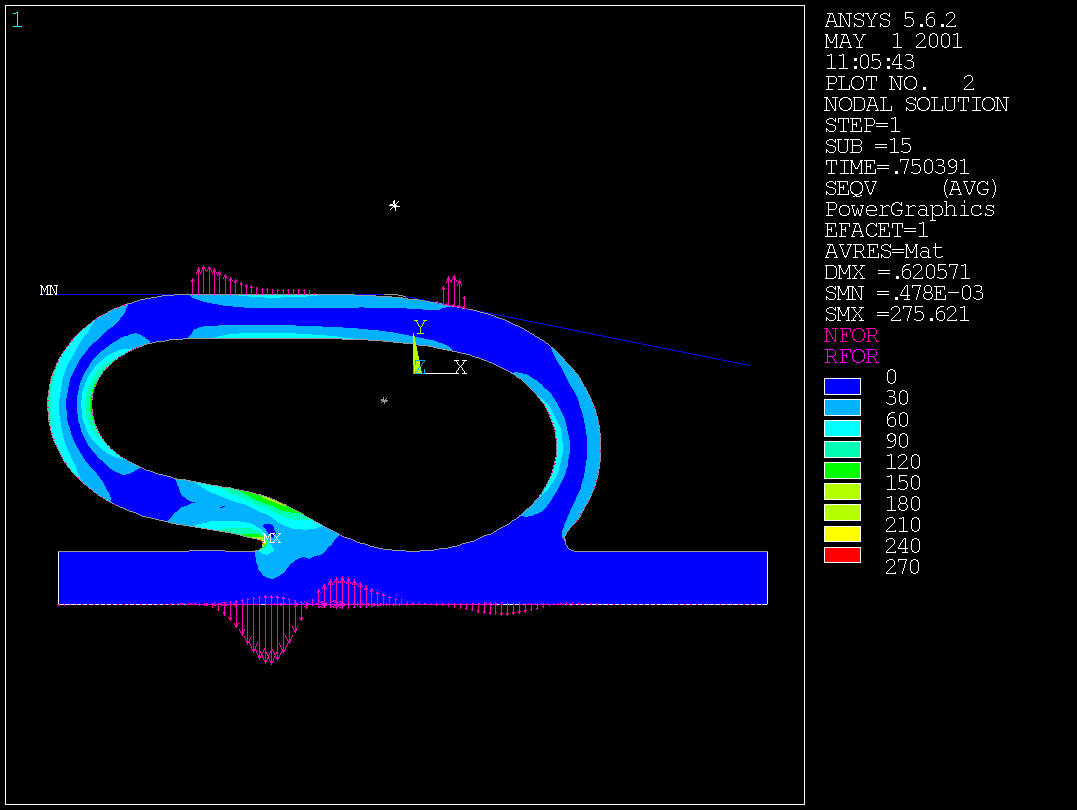

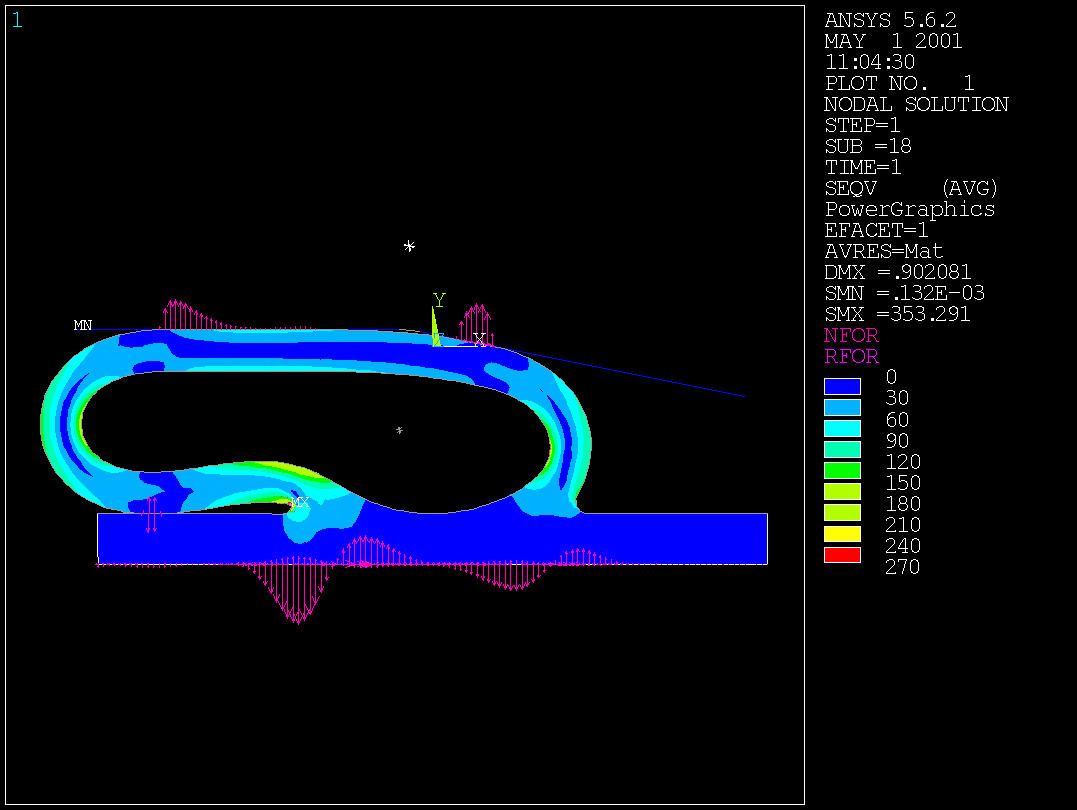

In this session we will simulate large deformation (stresses and deflections) of a rubber seal and its contact process with a trunk door when being pushed in. The complex shape of the seal also leads to rubber-rubber surface contact.

The purpose of the analysis is to examine the stresses and deflections

created within the rubber

during the closing of a door. The seal is made of a rubber material

and therefore is modeled using hyperelestic material properties.

Since the trunk door is much stiffer than rubber seal, the trunk door will

be modeled as a rigid body. Additionally, the rubber seal will come in

contact with itself. This contact must be taken

into accout explicitly, otherwise the seal will pass through itself.

New features

The basic steps for performing a typical surface-to-surface contact analysis are listed below:

Contact emelents are constrained against penetrating the target surface. However, the target elements can penetrate through the contact surface.

For rigid-to-flexible contact, the designation is obvious: the target surface is always the rigid surface and the contact surface is always the deformable surface.

For felxible-to-flexible contact, the guidelines are:

The ANSYS input file used in Spring 2002.

The model creation consists of six phases. The ANSYS log

files:

Seal-MR.part1,

Seal-MR.part2,

Seal-MR.part3,

Seal-MR.part4,

are made to give you essentially

step-by-step instructions. The different phases are:

SOLUTION HISTORY INFORMATION FOR JOB: seal.mntr

ANSYS RELEASE 5.6 .2 17:34:47 04/30/2001

LOAD SUB- NO. NO. TOTL INCREMENT TOTAL VARIAB 1 VARIAB 2 VARIAB 3

STEP STEP ATTMP ITER ITER TIME/LFACT TIME/LFACT MONITOR MONITOR MONITOR

CPU MxDs MxPl

1 1 1 1 1 0.50000E-01 0.50000E-01 19.750 -.35000E-01 0.78886E-30

1 2 1 1 2 0.50000E-01 0.10000 37.470 -.70000E-01 0.78886E-30

1 3 1 11 13 0.75000E-01 0.17500 149.45 -.12250 0.78886E-30

1 4 3 9 42 0.18750E-01 0.19375 430.70 -.13562 0.78886E-30

1 5 1 3 45 0.18750E-01 0.21250 467.09 -.14875 0.78886E-30

1 6 1 5 50 0.28125E-01 0.24062 522.28 -.16844 0.78886E-30

1 7 1 7 57 0.28125E-01 0.26875 596.30 -.18813 0.78886E-30

1 8 1 8 65 0.28125E-01 0.29688 679.88 -.20781 0.78886E-30

1 9 1 5 70 0.42188E-01 0.33906 735.54 -.23734 0.78886E-30

1 10 1 9 79 0.63281E-01 0.40234 832.39 -.28164 0.78886E-30

1 11 1 11 90 0.63281E-01 0.46563 948.03 -.32594 0.78886E-30

1 12 1 12 102 0.63281E-01 0.52891 1076.8 -.37023 0.78886E-30

1 13 1 11 113 0.63281E-01 0.59219 1188.7 -.41453 0.78886E-30

1 14 1 9 122 0.63281E-01 0.65547 1282.0 -.45883 0.78886E-30

1 15 1 8 130 0.94922E-01 0.75039 1366.1 -.52527 0.78886E-30

1 16 1 11 141 0.14238 0.89277 1478.1 -.62494 0.78886E-30

1 17 2 8 160 0.53613E-01 0.94639 1704.6 -.66651 0.78886E-30

1 18 1 11 171 0.53613E-01 1.0000 1822.1 -.70925 0.78886E-30

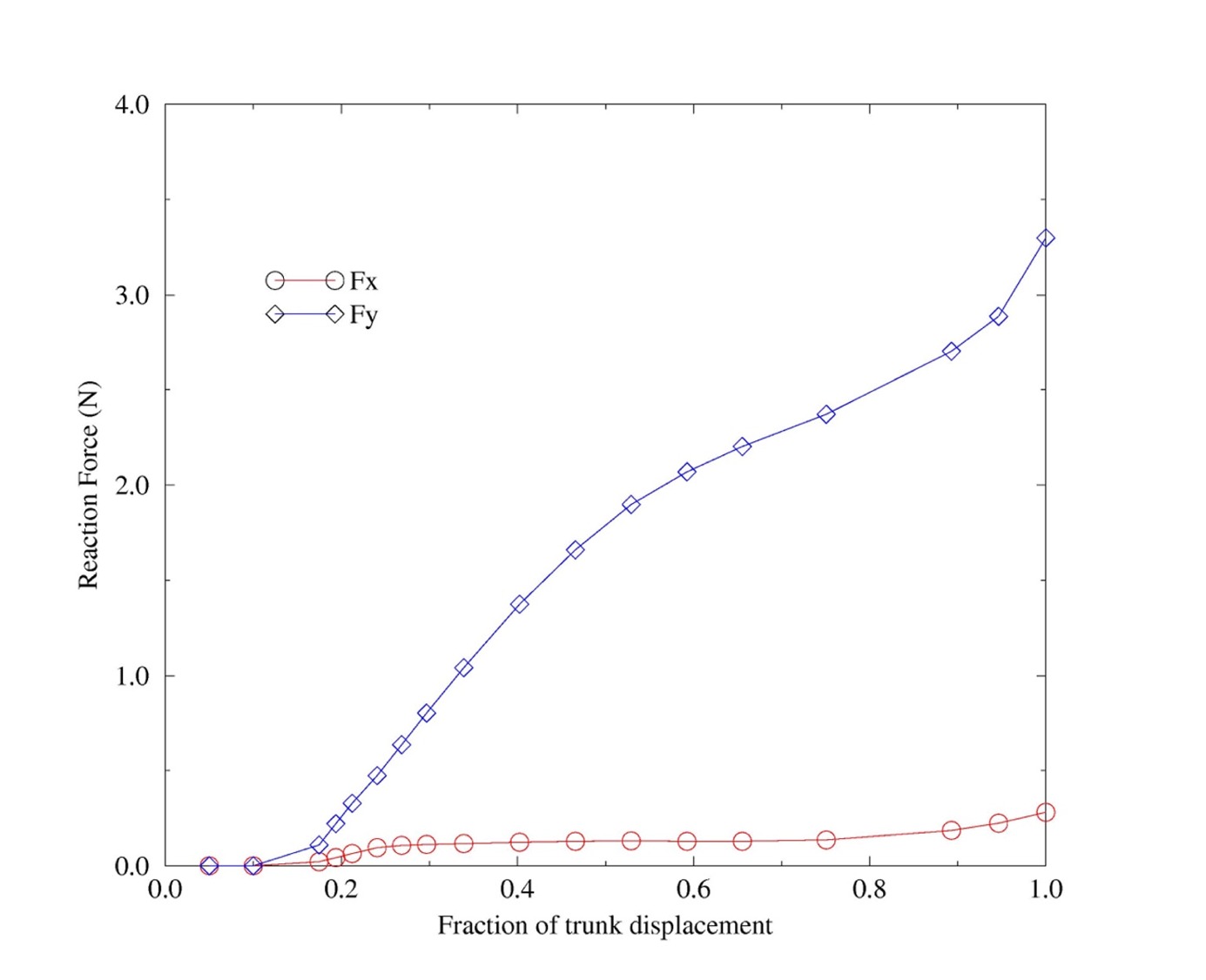

Results: Total push down = (-0.07,-0.7)